Linear Shower Drain

From $334.26 Regular Price $514.25

To $593.21 Regular Price $912.63

In stock

The best linear shower drain install methods. We are going to cover a few topics so we will break them down into sections so it is easy to follow along. Let's get started with our first section which is one of the most important parts of the entire project...

Research

Research is going to be the most important part of this entire process for this type of product. Understanding what the straight wet-area drainages install is for, how to use it, the positioning and overall look and feel of it's design and style are things you need to know and understand or at least have some concept of the idea so when you go hire a designer or a contractor to help you with this process, it's easier to help guide the conversation and get the overall look that you want because you understand what it is and how it can be used. Some of the research that you can do is obviously with Google, but it's more of the questions that you need to ask that are more important. Some of the things that you need to dig into in my opinion and some of the things that you may be able to answer right off the bat are one - Does this need to be handicap accessible? 4 inch square drains for your shower Are there any wheelchairs moving in or out or any other type of accessibility items that are going to be used to get in and out of the showering area? Number two - Do you want a curb or not? Is there anything that you want to step over when getting into your morning ritual? There are lots of people that don't have handicap accessibility things that they need, however with current trends this curbless sleek design is becoming more and more popular and it really creates an elegant look to the area, your room, your bathroom.

Now that you understand a good bit of research and some resources, a couple questions to kind of ask yourself before digging into this...there's also some other things that you kind of need to think about, not necessarily questions to ask yourself but just things to think about when looking at this type of product. What kind of style? What is the overall look and feel of the bathroom? Do you want it to match? Do you want a little bit contrast in thebath room? What about the color, the shape? How long do you want it? That your positioning in the wet-area room how to install your drain also has a big effect on the type of product and research that you need to be looking for when trying to get the right product for this job. See All Shower Drains

Where To Get It?

Well, Google is a wonderful resource. I know everybody says it and it's one of my favorite things to use, but how you use it and the questions you ask of Google really affect the results that you're going to find or receive. So one of the things that you need to look for in where to get this type of drainage is going to be understanding - like we talked about in number one - a little bit of the questions you need to ask yourself for the research, but you're going to now move into adding where to buy or where to get this kind of style or this color or this length or you know, asking the questions of "I want my drainage here, where do I get it?" One of the best things when installing a shower drain how to researching and trying to determine where to get an item is going to be actually calling companies and seeing what they can provide. Not everybody has the best online information or resources or installation guides or you being able to see and look at all of the angles in the product. So sometimes it's just better off calling the company and asking them some of these questions. "Hey, I'm looking for this style", "My entire room has this kind of a concept", "I have wheelchair needs that need to be handled, can you help me find a product that will allow me to do that?"

So where to find it is again just another researching topic. Some quick references that I will give you that kind of more pertain to an overall great system and design is one - going to be our product - which you will get. It works very well with our waterproofing system to give you a full envelope of lifetime warranties and those things and to look more into that please check out this article here or definitely give us a call or shoot us an email, we'll be able to help you out.

There are also other companies, and they are higher priced companies that provided similar types of materials. We can't say they're the same because they're not made in the same location, but they provide a bonded polyethylene membrane system and Trugard (us) also provide a bonded polyethylene membrane as well as three stainless steel linear drains. Both our company and the competitors provide a high caliber of quality, however we're at the medium to lower end price range and the name brands are more at the high-end price range. So I've talked about this in other things. In this we'll -- I'll dig deeper in part three here when I get into price points. But there is two places, there's also a few other companies. One is called -- I'll add that in via text later.

So now that you have a couple other places of where you can get it, you understand how to research and ask the right questions so that you will be provided with the kind of answers that you need - let's now move into the price point.

Now price point again ties into number one which is your research. It ties into number two of where to get it and that's going to basically give you a really good understanding and show you how you can consolidate that information and come up with a price point. If you're wanting really high end, solid 304 stainless steel high quality items at you know $50 pricing, you're not going to get it. However, you don't have to spend $1000 to get that exact same quality. Your drain smells bad? You can find it for more affordable and packaged as a kit. Keep that in mind when looking at your research. Your dollar doesn't always have to go to the brand name, but it will actually go to providing that same high quality for more affordability, which gives you a better ratio on your return on investment and the only reason the price points come up is because what are you doing with the area that you're trying to improve? Why are you looking for this type of product? Well, it's going to be for an office. It's going to be for your dream home that you're currently building. It's going to be for a remodeling because you're trying to sell and you know you need more value to upgrade to get a higher price. Well in all of those instances using that same dollar to buy a high end product you lose some of those margins per se that you would keep for yourself when you could get that same item for a different price point. So I always want to bring all these up when looking in the product research area, not just with us but in any circumstance this always comes up and I just think that when you do your research and you find the types of materials...for example, the 304 grade stainless steel, you know that's a good high quality product because the high end company sells it. So now what do you do? Well, you take that and say "Hey, I need this kind of material. I'm going to go shop on price." Now you're getting high quality for the

right price and it expands your margins on what you can keep in your pocket to do and spend more on other areas of your project to increase the value that you need to do to get the right kind of product. overall. So I just wanted to put that point across in the price point area to help you understand and have some good information on the research and things

Waterproofing

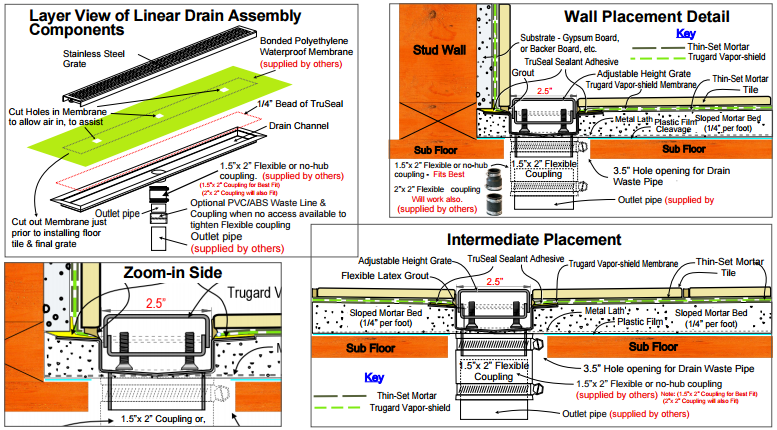

This is a huge part of installation, is going to be the waterproofing. Like I mentioned some of the questions in the beginning which were what kind of style of bathroom are you doing? Meaning - Do you want it curbless? Where do you want the position of the drainage? All these install questions come into play more here when it starts pertaining to waterproofing. So let me get a little bit into the process in order of an installation for this type of product. First of all and really in any product, number one - you need structure. What is a structure? 2x4s, cinder blocks, bricks, metal, metal framing...any of those will do when constructing the overall room and that's where you need to start.

Installation methods

Next you're going to need to look at "Okay, am I going to concrete board? Just regular drywall sheetrock? Am I going to use cement board? Concrete board? Purple board? Green board? What kind of board? Then I need to look at the company." So once you have determined that, you now have your walls covering your studs or whatever type of material your structure is. Okay, what about the floor? Are you going concrete slab on the first floor or are you on a second floor that's applied with substrate? That matters. So when you know what it is it's now time for you to determine how you're going to slope your floor to get the desired design and style that you want.

Now when talking about sloping your floor, there are certain codes that you need to do as per inspection and per your county office or your local inspectors. Give them a call. You need things to be as inspected as we're moving into this to make sure that you are approved and up to code. Please go to them for those as we cannot provide that kind of advice because we're not locally there or legally we can't do it. So now that you understand drains with tiled showers your surface and things like that, you know what's there, your walls maybe have drywall. Your floor is just a plywood floor. Maybe you cut a hole out because that's where your waste pipe is where all the water's going to flow out of. Okay, so now it goes into the positioning. It goes into of where you want your drainage. So that hole that has already been cut out where your waste pipe is, that may not be where you want to drainage. So first of all you need to move that waste pipe where you want the drainage. All of this should be pre-drawn, pre-discussed with the designer, your significant other...whatever it is to figure out the design and styles that you want before starting to cut and work in this process.

So now you have the drainage outlet and where you want it, you understand where it needs to go. Let's talk about putting a linear drainage hidden underneath bench, okay? So it's going to be on your right wall. If you are standing in front of the wet area, the drainage is going to be on the right and that means your slope all needs to slope to your drainage. All of our products come at a a quarter of an inch per foot, which is up to code in any area. So at a 1/4 inch per foot, your slope you're going to need to start from your left wall and go all the way to the right wall to where the drainage ends. So if you actually just go backwards from the drainage to your left wall you will know how far that is and if you do that by a quarter inch by foot you'll know the max height that that's going to be, okay?

Now because you're sloping left to right, that means your angle is not straight in front of you or straight away from you and therefore you're going to need a curb. Now that you get a curb, you're going to put a curb there in front of you. You are going to have to step into it and the water is going to flow left to right based on the slope that's up to code and flow into the linear drainage. So you will install the drainage, then the base that is pre-sloped, then you'll put in your bathroom curb.

Now we need to look at "Hey, I'm going to cover this thing with a bench." Now I need to find a bench that goes up against a wall that is raised off of the floor, has a structural capability of doing that and will allow me to hide the straight drainage. So now you'll install your bench. Now are there niches or shelves that you're going to need or want within your showering area? You will then install those. Once you're all done with that and putting in all the accessories, you need to move into waterproofing which is what this category is and you will waterproof all of it. Now that it's waterproofed, you can begin applying your finishing surface - whether it's stone, whether it's mosaic tiles, whether it's regular tiles, large format tiles, anything like that is now when you would start applying all of that, and then grout...and now you are finished.

Benefits and issues

Benefits for a straigt drainages really are a lot. It keeps things simple. The installation is easier. It looks nicer. It's cleaner. It's more elegant. It demands a higher value. It has a higher price range and it creates an overall feel of more of a sauna or spa like feeling which when either selling a home or moving into one it just makes for a really good feeling in that area. Some of the issues that can happen with drainages is when you don't get the ones that work well with shower waterproofing system. Some will have flanges that are beneath the height of the drainage and water won't be able to actually go into the drainage because when it seeps through your finishing surface - stone, tile, grout - it's all porous so it's going to soak up all the water and then it's going to go under it and so that's why you need a waterproofing. So if the water goes and hits up against that stainless steel drainage, it's going to sit there and puddle and when water sits and puddles it creates mold, mildew and it just gets really nasty really fast. So you need to make sure that to avoid issues you need to find a drainage that works well with a high quality waterproofing system. It will not cost any different. Price points won't change depending on that issue. So definitely go with one that solves the issue and doesn't create the issue.

Do your research. Don't overpay for the same product. Make sure it stays up to waterproofing standards and overall you know, good luck. We'd love to see your project. Contact us with your comments and questions, and that's it! Thanks for reading.

Our Trugard Linear Shower Drain series provides you the opportunity to design your restroom exactly as you desire it. Trugard offers distinct design sets that are ideal for little and large-sized wet-area floorings with different-- also tileable-- surface areas, such as in stainless-steel and glass. With the contemporary and ageless style grates, you have the opportunity to customize your wet-area experience.

We have straight wet-area drainages readily available for every kind of bathroom and installation circumstance, whether it's new building and construction or remodelling. Trugard straight wet-area drainages are available in lengths from 200 mm as much as 2000 mm and come with our trademarked innovations. In addition, all our wet-area drainages are easy to tidy and can be put nearly anywhere in the wet-area: complimentary in the flooring, against the wall or at the entrance.

With their high-design appeal, straight wet-area drainages make a declaration in the wet-area, however they also have a functional side. With point drainages pipes, wet-area bases must be sloped from all instructions to the drainage, for that reason limiting tile choice to mosaics or other fairly small-format tiles.

After developing and building your wet-area floor, you can think about a straight wet-area drainage as the final touch to an architectural masterpiece. You do not need to settle on a particular design or color restraint, either; direct wet-area drainage choices are a few of the most diverse in the redesigning market.

Think about the following information about wet-area floorings and direct drainages pipes if you're looking for some final wet-area flooring ideas prior to you start to invest in a renovating project. Because there is such a wide range of alternatives to choose from, a simple breakdown of the types, designs, and functions of these unique drainages pipes can assist to narrow down your options.

A straight wet-area drainage is a sleek and streamlined drainage that is usually formed in a rectangular fashion. It is a lengthened receptacle, a lot longer than conventional wet-area drainages pipes, and it is used to harness the flow of water into a single exit port, getting rid of water from your wet-area basin as rapidly and effectively as possible.

Not just have direct drainages pipes ended up being popular due to their innovative drainageing abilities, however likewise for their trendy style. They are a fantastic method to promote ornamental plumbing features, as they are flexible, subtle, and versatile to whichever style of wet-area floor you prefer.

Numerous large production brand names provide a range of direct wet-area drainage options that are made to mold with the preferred style of your wet-area. Each brand name comes geared up with patented technologies that keep the drainage working efficiently while preventing obstructions or overflow. Plus, each design can be hidden within the trench drains for the shower architecture of your wet-area, so you will not need to take a look at or step on a big drainage each time you enter.

No drainageing system is more streamlined and eco-friendly for your wet-area than a direct drainage. With a direct drainage, you aren't simply restricted to one design choice-- you can design it however you please.

Before jumping on the very first wet-area drainage you see, nevertheless, you need to take into consideration a couple of important elements. What are your style objectives for your wet-area?

Here's a breakdown of a few of the important things you ought to think of when pursuing the best straight drainage for your wet-area:

Connection

You now have the alternative to continue your wet-area floor style and integrate it into your direct drain. The majority of brands include a "tile-in" choice, where architects and plumbings can easily set up the flat drainage right into the tiles of your wet-area flooring. That method, there will be no visual disruptions between the drainage and the flooring, providing you a sleeker and more structured look.

Safety

Straight drainages are far safer than their traditional counterparts. Because they are flat versus the flooring of the wet-area, and they do not supply any barriers or metal grates, they are very safe and wheelchair friendly. Most professional straight drainage styles are ADA certified and satisfy all the standards and certifications for legal setup.

Upkeep Requirements

Drains are typically much easier to tidy than normal drainages pipes. This is because they typically feature a debris basket, which can be eliminated and cleaned with soap and water before being returned into the drainage. These drainages pipes also included the ability to prevent water overflow.

Location

Many straightwet-area drainages are so versatile that they can be positioned anywhere in your wet-area. This is because of the long lines and flat, smooth style of many drainages. Some designs even feature the ability to reduce or extend its size. Popular areas for direct drainages pipes include versus the wall or sides, rather than in the center of the wet-area.

There's no doubt that straight wet-area drainages are quickly ending up being a popular favorite amongst house owners all over. Understood as trench drainages pipes, these drainages pipes feature simply that: A trench-like system that utilizes the flow of water and drainages it all in one continuous movement so that your wet-area never ever becomes blocked or too backed up with water. This is an ideal choice for walk-in wet-areas however can be utilized for connected wet-areas and bath tubs.

Did you know that the original design for retail drainages was inspired by the kinds of drainages utilized in dining establishments and high school locker rooms? It was discovered that the long, trough-like shape of the elongated drainages was more effective at sucking water away.

One of the greatest advantages of direct wet-area drainages is that they can be positioned flush against a wet-area wall, offering you the optimum quantity of smooth floorspace possible for your feet. These drainages pipes make the wet-area quickly accessible, and they can not be tripped over or stepped on in an agonizing manner.

A big hole in the floor does not go with your wet-area's design, so it is a good idea you discovered direct wet-area drainages pipes for your job. Straight wet-area drainages can be easy slatted grates, complex styles, or practically invisible so you can find the best type to match your wet-area's style. Direct wet-area flooring drainages pipes differ in length with much shorter drainages pipes around 10 inches to 72 inches or longer to best fit the shapes and size of your wet-area. You require a drain with a tile insert grate if you desire a nearly invisible drainage for your wet-area. These permit you to connect tile to the grate itself, and many already function bonded spacers for easy installation of your tile. Your wet-area needs a small slope towards the drainage in order to work appropriately, but wet-area drainage sets consist of the water resistant membrane and other items to ensure you have all of the required parts prior to you start to tile. Straight wet-area drainages pipes are a beautiful alternative to round drainages, and the big inventory of designs on Trugard has you covered with everything you require to begin.

Trugard invites you to explore the possibilities for the straight wet-area drainage of your dreams! Our ingenious products have actually transformed wet-area design, integrating appealing form and simple and easy function in our easy-to-install straight drainage systems.

| Features |

The TRU-LINE Linear Drain consists of a formed stainless steel channel body and a grate assembly that can be seamlessly adjusted to the thickness of the ceramic tile or stone covering from 1/4" to 1". The channel body features a standard 2" no-hub outlet and is attached to the pipe using an appropriate flexible or no-hub coupling. The simple connection to standard drain outlets makes TRU-LINE suitable for new construction and renovation. Available in 7 sizes and 3 styles. Each linear drain comes with a 10.3oz adhesive sealant Sizes:

Styles:

|

|---|